Besides some point-and-click educational software and watching my brother play Bugdom on the iMac G3, my first gaming experiences included playing Age of Empires II, GTA Vice City, and Gothic on my friends’ computers, later on my own. I was so hooked that I got up at 3 in the morning on schooldays, snuck into the basement, and played until 6, barely missing my parents getting up so that I would not get in trouble. I cheated because back then cheating was still fun.

Nowadays, I would not get out of bed if GTA VI and Half Life 3 were given away on Steam for free. For the first time in my life, I can afford high-end hardware, but it hardly makes any difference in terms of fun. Most importantly, my childish fascination with video games remains, and the only thing I regret is not having enough time to play them all.

To be honest, I also analyze games more from a technical standpoint now, which can sometimes destroy the immersion, but this downside is compensated by the joy I get from developing games. I still consider myself an absolute amateur, and getting into indie game development is tough, for it is the most supreme discipline, combining all different kinds of art formats, such as writing, programming, graphic design, 3D modeling, movie making, composing, and recording music.

Accordingly, the bar needed to be set low at first, and instead of beginning work on the open world MMORPG of my dreams, with raytracing, mods, and in-game payments, I made some rather elaborate text adventure games. While the results were not flawless, and I was unable to port them to other operating systems than Windows—let alone mobile phones—I learned a great deal about coding, even building my own engine or at least framework from scratch.

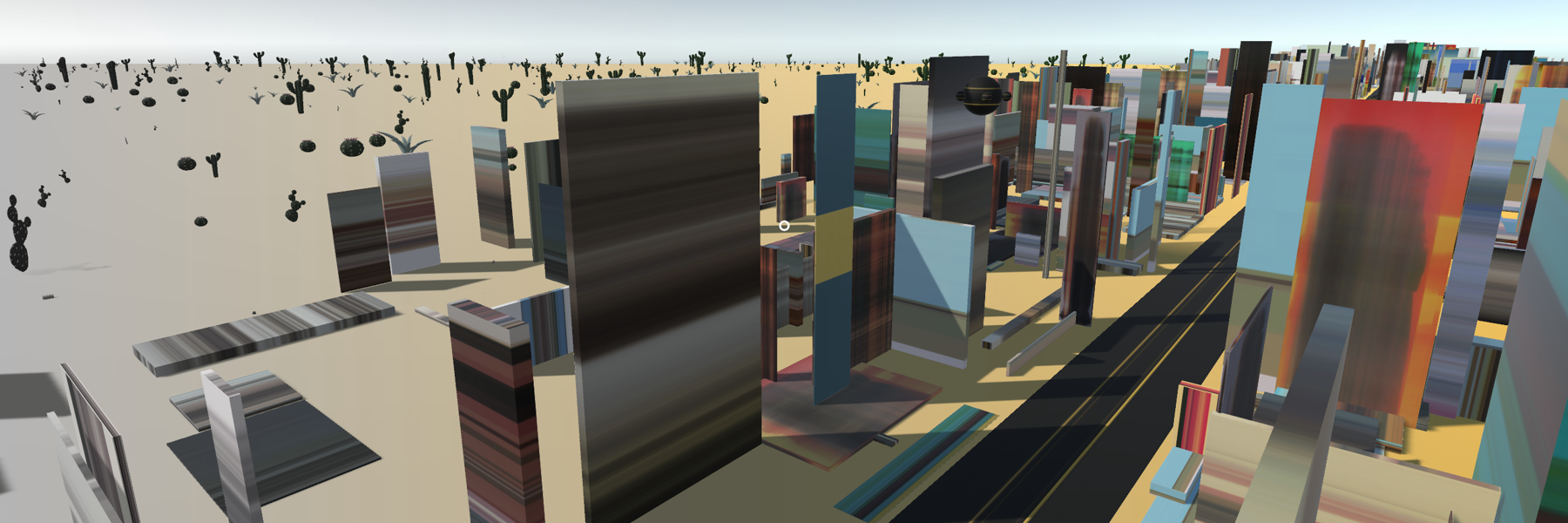

Later on, I used the Processing coding language and Unity game engine to make some prototypes of games with graphics, although the controversy over Unity’s greedy and vile backstabbing in 2023 is forcing me to reconsider switching to another game engine.

Below, you can find the attempts I made so far.

Simultaneously, I am still playing games whenever I find the time (or whenever I am not currently writing content for this homepage). My focus lies on immersive single-player games with minimalist UI, 3D graphics, RPG elements, and good narrative. I also do not mind bleakness, guns, gore, or a little horror, but be assured that I also put well over a thousand hours into running a Minecraft server with friends, back when Mojang was not owned by Microsoft. Additionally, I love writing Steam reviews and hunting for achievements—as long as they do not escalate into days of grinding.

Here are most of my favorite games (when I played more than one title, I simply listed the franchise): Age of Empires, Age of Mythology, Anno 2070, Banished, Battlefield 2, BioShock, Breathedge, Call of Duty, Control, Cossacks, Crysis, Cyberpunk 2077, Don’t Starve, The Elder Scrolls, Elex, Empire Earth, Fallout, The Forest, The Forgotten City, Gothic, Grand Theft Auto, Hogwarts Legacy, Horizon: Zero Dawn, Kingdom Come: Deliverance, Layers of Fear, The Lord of the Rings: Battle for Middle-earth, Mass Effect, Metro Exodus, Minecraft, Modern Warfare, Mount and Blade II: Bannerlord, No Man’s Sky, The Painscreek Killings, Portal, Risen, S.T.A.L.K.E.R.: Shadow of Chernobyl, SOMA, The Sims, Star Wars: Battlefront II (2005), Subnautica, Valheim, The Witcher 3: Wild Hunt, Worms World Party.